What is an Optics Cleanse?

The dust filters on projectors are unable to prevent the ingress of microscopically fine dust, especially with LCD projectors. This dust forms a stubborn film on each optical surface within the optical engine, and it cannot be removed with conventional on-site servicing methods. Typically, there are 40 optical surfaces inside the engine, and if each of these has a transmission or reflectivity reduction of 2%, only 44% of the original light output will reach your projection surface. The optical engine is a sealed unit buried within the projector, and is inaccessible without specialist knowledge and equipment.

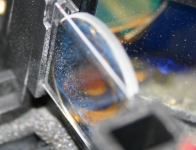

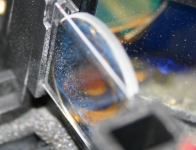

Dust on a filter inside the optics engine

At our Projector Clinic, we have the specialist facilities to professionally cleanse the optics engine. This is the process that we follow:

1. We check the condition of the projected image on-site - This verifies that the projector work, and any significant defects that we should be aware of.

2. We remove the projector and take it to the Projector Clinic - Any screws or fixings are retained.

3. We measure the light output before we start - We measure the lux and calculate the lumens of the projected image as viewed, and photograph the red, blue, green, white and black outputs for later comparison. If there are any particular image defects such as LCD burn, we record these.

4. We dismantle the projector - In a typical projector, there are 55 screws, 13 PCB connectors and 13 sub-assembly components to remove. Everything must be done in a strict sequence, and each item retained. The PCBs are all sensitive to electrostatic discharge, so ESD protection is essential to prevent shortening the projector life. The connectors are delicate and must not be damaged.

The projector PCB is sensitive to ESD

5. We open the optics engine - This is a sealed unit, inside which is a complex array of Fresnel lenses, ultraviolet filters, dichroic glass, chromatic filters, mirrors, lenses, LCD panels, polarizing filters and prisms. Typically, there are 40 optical surfaces that must be removed and cleaned in an ultrasonic cleaning tank to remove the stubborn film of ultra-fine dust. Each of the surfaces must be polished before being re-fitted. The alignment of the LCD panels on the prism sub-assembly must not be disturbed, and some items must be cleaned en-situ.

LCD panels,, filters and prism sub-assembly

6. We re-build the projector - This is a reverse of step 4. Care must be taken to ensure that the optics engine is sealed to prevent the ingress of dust. All filters must be fitted correctly to prevent UV light from the HID lamp passing through to the lens.

7. We clean the measure the light output of the projector again - We measure the light output and calculate the difference to verify the degree of improvement that we have achieved.

8. We return to the school to re-fit the projector - When we re-fit the projector, we re-align the image with the interactive whiteboard, and leave it ready for use.

The dust filters on projectors are unable to prevent the ingress of microscopically fine dust, especially with LCD projectors. This dust forms a stubborn film on each optical surface within the optical engine, and it cannot be removed with conventional on-site servicing methods. Typically, there are 40 optical surfaces inside the engine, and if each of these has a transmission or reflectivity reduction of 2%, only 44% of the original light output will reach your projection surface. The optical engine is a sealed unit buried within the projector, and is inaccessible without specialist knowledge and equipment.

Dust on a filter inside the optics engine

At our Projector Clinic, we have the specialist facilities to professionally cleanse the optics engine. This is the process that we follow:

1. We check the condition of the projected image on-site - This verifies that the projector work, and any significant defects that we should be aware of.

2. We remove the projector and take it to the Projector Clinic - Any screws or fixings are retained.

3. We measure the light output before we start - We measure the lux and calculate the lumens of the projected image as viewed, and photograph the red, blue, green, white and black outputs for later comparison. If there are any particular image defects such as LCD burn, we record these.

4. We dismantle the projector - In a typical projector, there are 55 screws, 13 PCB connectors and 13 sub-assembly components to remove. Everything must be done in a strict sequence, and each item retained. The PCBs are all sensitive to electrostatic discharge, so ESD protection is essential to prevent shortening the projector life. The connectors are delicate and must not be damaged.

The projector PCB is sensitive to ESD

5. We open the optics engine - This is a sealed unit, inside which is a complex array of Fresnel lenses, ultraviolet filters, dichroic glass, chromatic filters, mirrors, lenses, LCD panels, polarizing filters and prisms. Typically, there are 40 optical surfaces that must be removed and cleaned in an ultrasonic cleaning tank to remove the stubborn film of ultra-fine dust. Each of the surfaces must be polished before being re-fitted. The alignment of the LCD panels on the prism sub-assembly must not be disturbed, and some items must be cleaned en-situ.

LCD panels,, filters and prism sub-assembly

6. We re-build the projector - This is a reverse of step 4. Care must be taken to ensure that the optics engine is sealed to prevent the ingress of dust. All filters must be fitted correctly to prevent UV light from the HID lamp passing through to the lens.

7. We clean the measure the light output of the projector again - We measure the light output and calculate the difference to verify the degree of improvement that we have achieved.

8. We return to the school to re-fit the projector - When we re-fit the projector, we re-align the image with the interactive whiteboard, and leave it ready for use.